Los motores radiales impulsaron algunos de los aviones más legendarios de la historia. Tienen un diseño único que proporciona alta potencia, durabilidad y confiabilidad. El aspecto clásico de estos motores de avión los convirtió en un elemento básico de la aviación antes de que los motores a reacción tomaran el control.

Tomemos un momento para entender cómo funcionan estos motores y por qué fueron tan ampliamente utilizados.

RESUMEN

-

Los motores de aviación radiales disponen los cilindros en un patrón circular alrededor de un cigüeñal central.

-

El motor radial ofrece mejor refrigeración por aire y durabilidad en comparación con el motor en línea.

-

El sistema de varilla maestra y varilla articulada hace que su funcionamiento sea único.

-

La aviación moderna ha sustituido en gran medida los aviones con motores radiales por turbinas.

Los orígenes de los motores radiales

Retrocedamos un poco en el tiempo. Los motores radiales se remontan a principios del siglo XX, incluso antes del primer vuelo con motor de los hermanos Wright.

El concepto del motor radial ganó fuerza por primera vez cuando CM Manly desarrolló un motor radial de cinco cilindros refrigerado por líquido para el avión Aerodrome de Samuel Langley.

En aquella época, los motores radiales competían con los motores rotativos y en línea refrigerados por agua.

Al final de la Primera Guerra Mundial, los motores radiales terminaron superando a los motores rotativos tanto por su eficiencia como por su potencia de salida.

Durante la Segunda Guerra Mundial, los motores radiales de aviación se convirtieron en la principal opción para los aviones militares y propulsaron bombarderos como el B-17 Flying Fortress y el B-25 Mitchell.

Su construcción sencilla los convirtió en una opción ideal para la aviación, además del hecho de que son motores radiales refrigerados por aire. A diferencia de los sistemas de refrigeración líquida de los motores, los motores radiales no requerían sistemas de refrigeración complejos, lo que reduce su peso total y mejora su durabilidad.

Evolución de los motores radiales

Después de que se introdujeran estos motores, los motores radiales evolucionaron rápidamente. Los primeros modelos eran relativamente pequeños y producían una potencia limitada, pero a medida que los avances en la metalurgia y los sistemas de combustible continuaron, permitieron una mayor potencia de salida.

En las décadas de 1920 y 1930, fabricantes de aviones como Pratt & Whitney y Wright producían potentes motores radiales de gran cilindrada capaces de propulsar aviones comerciales y bombarderos militares.

Uno de los principales avances fue el lanzamiento de los motores radiales de doble fila, que apilaban dos juegos de cilindros en una configuración radial para duplicar la potencia sin aumentar el diámetro del motor.

Este desarrollo permitió que aviones como el Boeing B-29 Superfortress volaran distancias más largas y transportaran cargas útiles más pesadas.

¿Cómo funciona un motor radial?

Entonces, ¿cómo funciona exactamente un motor radial? Básicamente, un motor radial sigue el mismo ciclo de cuatro tiempos que otros motores de combustión interna:

-

Consumo

-

Compresión

-

Fuerza

-

Escape

Pero su configuración única lo distingue del resto.

Los cilindros están dispuestos en círculo alrededor del cigüeñal y, por lo general, tienen una configuración impar (cinco, siete o nueve cilindros por fila). El motivo de esta extraña disposición es que permite un orden de encendido parejo.

Cada motor radial tiene una biela maestra que está conectada directamente al cigüeñal. Los pistones restantes se unen a la biela maestra mediante bielas articuladas que les permiten moverse sincronizados. El diseño minimiza las vibraciones y garantiza que la potencia llegue a la hélice.

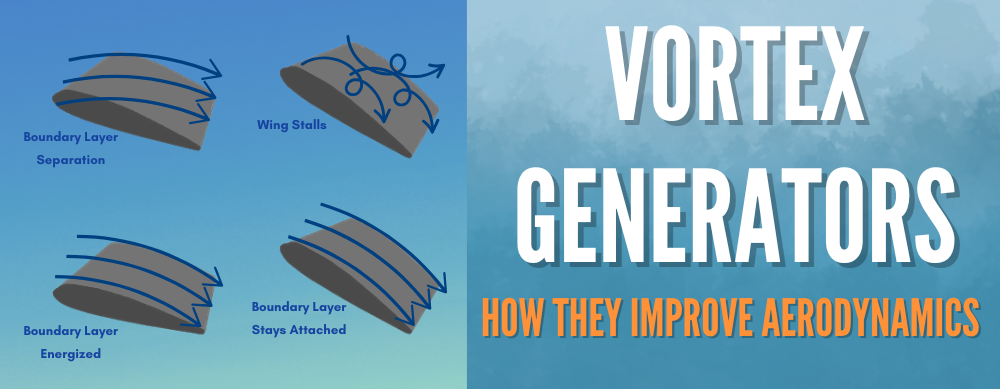

Como los motores radiales se enfrían por aire, su disposición de cilindros abiertos permite que el flujo de aire llegue a cada pistón de manera uniforme. Sin embargo, los motores radiales de varias filas a veces tienen problemas con la refrigeración, ya que el flujo de aire hacia los cilindros traseros es limitado.

Sistema de varilla articulada y varilla maestra

Las bielas maestras son muy importantes para el funcionamiento de los motores radiales. A diferencia de los motores en línea, donde cada cilindro tiene su propia conexión al cigüeñal, los motores radiales tienen una biela maestra que se conecta directamente al cigüeñal. Los demás cilindros se conectan a puntos de pivote en la biela maestra.

La configuración permite que todo el conjunto gire sin problemas y reduce el desgaste al tiempo que proporciona una entrega de potencia constante.

Ventajas de los motores radiales

Los motores radiales proporcionaban varias ventajas que los convirtieron en la opción preferida para los primeros aviones:

-

Refrigeración por aire: como los motores radiales no requieren refrigeración líquida, eliminan la necesidad de radiadores, lo que reduce el peso total de la aeronave.

-

Durabilidad: La construcción simplista, el cigüeñal más corto y menos piezas móviles hacen que los motores radiales sean increíblemente robustos y resistentes a los daños.

-

Confiabilidad: Su diseño minimiza las vibraciones, por lo que hay un funcionamiento suave y menos fallas mecánicas.

-

Potencia de salida: los motores radiales pueden producir una buena cantidad de caballos de fuerza, lo que los hace adecuados para aeronaves grandes y pesadas, como bombarderos y aviones de transporte.

-

Facilidad de mantenimiento: debido a que los motores radiales carecen de sistemas de enfriamiento complejos y tienen acceso abierto a los cilindros, los mecánicos pueden inspeccionarlos y repararlos fácilmente sin un tiempo de inactividad significativo.

A pesar de todos estos beneficios, los motores radiales tienen algunos inconvenientes, principalmente relacionados con la aerodinámica y los desafíos de refrigeración en configuraciones de varias filas.

Consideraciones aerodinámicas

Los motores radiales tienen una clara desventaja en comparación con los motores en línea o los motores tipo V: crean una resistencia considerable.

La forma circular y grande altera el flujo de aire alrededor del avión y lo hace menos efectivo a altas velocidades. Los ingenieros intentaron solucionar este problema con carenados aerodinámicos y aletas de refrigeración, pero siguió siendo un factor limitante.

Desafíos y decadencia de los motores radiales

Si bien los motores radiales eran buenos para su época, tenían limitaciones:

-

Resistencia aerodinámica: Su gran área frontal crea más resistencia que los motores en línea aerodinámicos.

-

Limitaciones de enfriamiento: Los motores radiales de varias filas tienen dificultades para proporcionar un enfriamiento uniforme a todos los cilindros, y eso requiere soluciones de enfriamiento adicionales.

-

Tamaño y peso: El diseño más voluminoso hace que sea más difícil integrarlos en diseños de aeronaves elegantes y de alta velocidad.

-

Configuración limitada de válvulas: debido a su diseño, la mayoría de los motores radiales utilizaban un sistema simple de dos válvulas por cilindro, lo que terminó restringiendo su potencia potencial.

Después de la Segunda Guerra Mundial, los avances en la propulsión a chorro llevaron a la sustitución gradual de los motores radiales. Los motores a reacción proporcionaban mayor velocidad, uso y relación potencia-peso. Con el tiempo, se convirtieron en la mejor opción para la aviación moderna.

Los turbohélices y el fin de una era

El auge de los motores de turbohélice en la década de 1950 contribuyó a disminuir aún más el uso de los motores radiales. Los turbohélices aportaron la fiabilidad de los motores a reacción, pero conservaron la capacidad de propulsar aviones de hélice.

La transición a los aviones a reacción marcó el fin de los motores radiales como motor principal tanto para la aviación comercial como militar.

Aviones famosos que usaban motores radiales

Muchos aviones legendarios dependían de motores radiales:

-

B-17 Flying Fortress: Un bombardero pesado equipado con cuatro motores Wright R-1820 Cyclone.

-

B-25 Mitchell: Un bombardero bimotor versátil que utiliza ciclones Wright R-2600 Twin Cyclones.

-

P-47 Thunderbolt: Un caza de alto rendimiento propulsado por el Pratt & Whitney R-2800 Double Wasp.

-

Douglas DC-3: Uno de los aviones comerciales más famosos, que utiliza ciclones Wright R-1820.

-

Grumman F8F Bearcat: Un poderoso caza naval que utilizaba motores radiales para maniobras de alta velocidad.

El legado de los motores radiales

Aunque los motores radiales ya no son la opción principal para la aviación, aún ocupan un lugar en la historia y en aplicaciones específicas:

-

Aeronaves históricas: Muchas aeronaves restauradas de la Segunda Guerra Mundial continúan utilizando motores radiales, manteniendo viva la historia de la aviación.

-

Aplicaciones industriales: Algunos generadores y maquinaria agrícola todavía dependen de diseños de motores radiales.

-

Aeronaves experimentales y de construcción casera: los entusiastas restauran y construyen aviones con propulsión radial, manteniendo viva la ingeniería para las generaciones futuras.

-

Conversiones de motores radiales: algunos entusiastas de la aviación modifican motores radiales para usarlos en automóviles, motocicletas y proyectos personalizados.

Preguntas frecuentes

-

¿Por qué los motores radiales ya no son comunes?

Los motores radiales fueron reemplazados por motores a reacción y mejores motores de pistón debido a sus limitaciones aerodinámicas y diseños más voluminosos.

-

¿Cómo se enfrían los motores radiales?

La mayoría de los motores radiales utilizan refrigeración por aire, y el flujo de aire llega naturalmente a los cilindros expuestos. Sin embargo, los radiales de varias filas a menudo requieren soluciones de refrigeración adicionales para evitar el sobrecalentamiento.

-

¿Hay aviones modernos que utilicen motores radiales?

Aunque es poco común, algunas aeronaves pequeñas y aviones experimentales aún utilizan motores radiales, principalmente con fines históricos o entusiastas.

Llevar

Los motores radiales revolucionaron la aviación y sorprendieron al mundo con su potencia, fiabilidad y durabilidad. Aunque prácticamente han desaparecido de las aeronaves modernas, el legado que crearon sigue vivo en aviones históricos, museos y comunidades de aviación.

¿Interesado en aprender más sobre aeronaves?

Consulte nuestras otras guías sobre motores de pistón, turbohélices y sistemas de propulsión a chorro para ampliar sus conocimientos sobre la tecnología de la aviación.

-

Diferencias entre motores turbohélice y motores de pistón: eficiencia y seguridad

-

Aviones personales asequibles que se ajustan a su presupuesto

¿Le resultó útil este artículo?

¿Crees que nos hemos olvidado de alguna pregunta importante de la entrevista? ¡Cuéntanoslo en los comentarios a continuación!