As your jet plane turns onto the runway you eagerly anticipate the takeoff. Suddenly, you are startled by a loud bang and flash of fire from one of the engines. What's going on? Is everything alright?

If you don't have experience with gas turbine engines, you may not be familiar with compressor stalls. But if you happen to encounter one, it's an experience you won't soon forget.

In this article, we'll delve into the world of compressor stalls—what they are, how to handle them, and how to avoid them altogether.

What is a Compressor Stall?

What is a Compressor Stall?

Compressor stall is common in gas turbine engines where airflow is suddenly disrupted, causing potential damage to the compressor stages. A similar but more severe issue, known as compressor surge, can result in a complete halt of airflow and must be carefully monitored and prevented to maintain engine functionality.

What Causes a Compressor Stall?

A stall in the compressor occurs within turbine engines when the smooth airflow over the compressor blades is disrupted, leading to a momentary power drop and a loud bang in some cases.

This can happen at low altitudes and high speeds, such as during a take off.

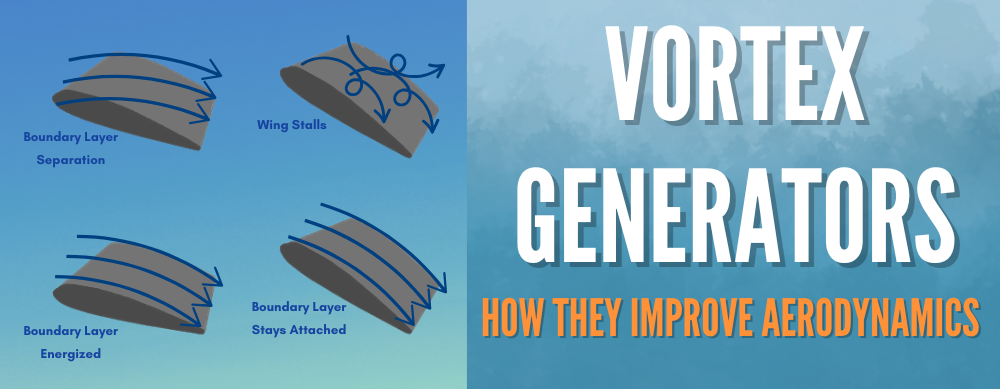

These stalls happen when the air flow over the blade becomes stuck or separates, causing a disturbance in the compression process.

Typically, during normal operation, air enters the engine, passes through the compressor stages where it's compressed, mixes with fuel in the combustion chamber, and then expands through the turbines to generate thrust.

However, during a compressor stall, this process is interrupted. The previously compressed air in the compressor stages encounters a disruption, often due to changes in engine operating conditions, leading to unstable airflow patterns.

If the pilots do not manage it properly, it can lead to a more severe issue called a compressor surge, where the airflow comes to a complete halt, potentially causing significant damage to the engine components and requiring careful monitoring and prevention techniques to help maintain engine functionality.

Key Causes of a Compressor Stall or Surge:

-

Foreign object damage, sand, and dirt erosion can lower the surge line.

-

Built-up dirt in the compressor or wear increases the operating line.

-

Bird strikes cause complete loss of surge margin and surging during ground, takeoff, low level flying, and landing.

-

Debris on runways and flight decks can also cause damage.

-

Aircraft operations outside the design envelope or manual procedures can raise operating lines and lead to surging.

-

Turbulent or hot airflow into intake or use of reverse thrust can also cause re-ingestion of hot air or gases. Gun firing may produce inlet distortion.

How to Recover from a Compressor Stall

How to Recover from a Compressor Stall

If a compressor stall occurs, pilots should follow procedures or guidelines that are designed for their specific aircraft type and engine. Usually this involves, reducing thrust on the affected engine. Modern engines have systems in place to prevent stalls, but pilots should still be cautious.

-

Throttle Response

Immediately adjust the throttle on the affected engine to reduce power. Steadily decrease the thrust on the affected engine. Gradually reducing power can help stabilize the airflow and prevent further issues.

Monitor the engine instruments carefully and keep an eye on the temperature. This action can often correct the disrupted airflow and restore normal engine function, depending on the cause of the stall.

-

Leveling Off

Adjust the angle of attack (AOA) or level off the aircraft. Changing the AOA can aid in restoring normal airflow over the compressor blades, possibly allowing the engine to resume normal operation.

-

Engine Restart

In the event of a persistent stall or engine shutdown, it may be necessary to perform a full restart of the engine. This must be done in accordance with the manufacturer's guidelines and all necessary safety precautions should be taken into consideration.

-

Maintenance and Repair After Landing

Following a compressor stall, have an aviation mechanic conduct maintenance and repair to address engine issues. Such as, repairing damaged compressor blades, removing foreign objects, or additional preventative measures.

Following these steps can help mitigate a stall and restore engine function, but it's important to consider the engine type and conditions first.

How to Prevent Compressor Stalls

How to Prevent Compressor Stalls

Preventing compressor stalls in turbine engines involves proactive measures that include adjusting the effective angle of attack and managing air pressure to maintain optimal airflow conditions.

-

Angle of Attack: Pilots can help prevent compressor stalls by being careful about the aircraft's critical angle, or angle of attack (AOA). Having a pilot diagnose and adjust the AOA during a flight can help in maintain a stable airflow over the compressor blades, and reduce the risk of stalls.

-

Air Pressure: Techniques such as bleeding off air at specific engine RPM ranges or utilizing variable Inlet Guide Vanes and stator blades help in managing air pressure within the engine. These mechanisms mitigate reverse flow and maintain the engine operating line within safe limits, minimizing the chances of stalls and surges.

-

Throttle: Avoiding sudden and rapid throttle changes. Abrupt adjustments can create mismatches between airflow and compressor characteristics, leading to disturbances that might trigger stalls or an engine surge.

-

Inlet Distortion: Preventing inlet distortion is a necessity since it can reduce the stall margin and cause local stalls or surges. Keeping a uniform and steady airflow into the engine minimizes the risk of disruptions to the compressor's smooth operation.

-

Regular Maintenance: Regular maintenance and inspections can help identify potential issues that can lead to a stalled jet engine.

By actively managing the angle of attack, controlling air pressure, avoiding rapid throttle changes, and ensuring inlet stability, pilots and engine operators can help reduce the likelihood of compressor stalls and surges in gas turbine engines.

Real Examples of a Compression Stall

The best way to understand this type of stall is to witness it in action. Check out these videos to see how these stalls appear to both passengers and pilots.

This video offers an in-depth look into a compressor stall that took place right after takeoff for this Aer Lingus Airbus.

This video uploaded by a passenger allows you to clearly hear when the compressor stall occurs and see the decision made by the pilots to land and get it checked out.

Takeaway

Pilots must be proactive in preventing compressor stalls and surge for safe and optimal engine performance. This includes monitoring engine behavior, adjusting angle of attack, and managing throttle techniques.

Strategic measures such as air pressure management and avoiding rapid throttle changes can significantly reduce the risk of disruptions and enhance safety during flight.

Be sure to check with official sources and professionals for questions you have regarding engine maintenance and safety.

Understanding these aspects allows pilots to maintain a vigilant approach and promote efficient engine operations.

Fly safe!

Want to know more about engines and stalls?

Our guides are designed to help student pilots become professional pilots and for private pilots to brush up on their knowledge and skills.

Did you find this article helpful?

Do you think we missed anything important or made a mistake? Let us know in the comments below so we can correct it!

|

ASA Turbine Pilot's Flight Manual, 4th EditionProviding basic knowledge essential for all pilots, from beginning students through to the advanced certificates, this Federal Aviation Administration (FAA) publication introduces readers to the broad spectrum of knowledge required as they progress through pilot training. |