What is De-Icing?

What is De-Icing?

Why do Planes Need De-Icing?

Airplane de-icing is a critical procedure during winter weather conditions to ensure the safety and optimal performance of the aircraft.

This process is essential to prevent ice formation along with, snow, frost, or other contaminants on crucial areas of the aircraft skin such as wings and stabilizers, as it can have detrimental effects on the four forces of flight—drag, lift, thrust, and weight.

Why De-Icing is Essential

Why De-Icing is Essential

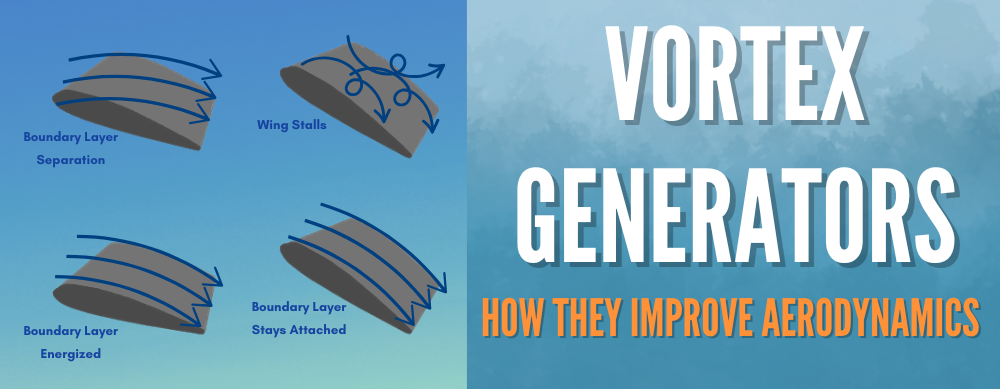

If allowed to accumulate, contaminants can disrupt critical airflow, leading to increased drag, decreased lift, reduced thrust, and increased weight. This disruption can result in turbulence, a decreased stall angle of attack, and, in severe cases, even a crash.

Potential Consequences of Skipping De-Icing

Skipping the process of removing ice can lead to a range of issues, including decreased stall angle of attack, loss of control due to ice buildup on control surfaces, and the possibility of ice breaking off during flight and causing engine issues.

When to De-Ice Your Airplane

When to De-Ice Your Airplane

While ice removal may seem necessary only during snowy or icy conditions, even seemingly benign frost can be a cause for concern. The Federal Aviation Administration (FAA) has a ground de-icing program that emphasizes the importance of having a clean aircraft with no contaminants before takeoff.

Parts Recommended for De-Icing by FAA

The FAA takes deicing seriously and has put in place a very specific and detailed guide to international de/anti-icing procedures. The regulations standardize the handling and application of deicing compounds as well as the timeline and documentation that must be followed for each application.

The FAA recommends inspecting and remove ice from the following areas:

- Antennas and sensors

- Control surfaces and gaps

- Engine inlets and fan blades

- Fuselage

- Landing gear and landing gear door

- Pitot heads and static ports

- Propellers

- Leading edges

- Vertical and horizontal tail surfaces

- Wings and all other aerodynamic surfaces

What is Used to De-Ice Airplanes

What is Used to De-Ice Airplanes

When de-icing your plane, a de-icing compound comprised of propylene glycol and water is used to remove contaminants like ice, snow, and frost. Different types of de-icing fluid, such as Type I, with specific holdover times, can be selected based on weather conditions and desired effectiveness.

-

Types of De-Icing Fluids:

-

Type I: Less viscous, orange dyed anti icing fluid for temperatures down to 22°F.

-

How to De-Ice Your Airplane

Ice Removal: Commercial Plane

To deice a commercial airplane, deicing chemicals are put into a blend and heated to approximately 130-180°F and sprayed onto the aircraft through a high-pressure hose. As the pilot, you will work with the ground crew to make a joint determination on which aircraft surfaces require deicing, which type of fluid to use, and whether manual deicing is required for select areas.

It is important for the pilot and crew to know the no-spray areas of their aircraft and plan deicing accordingly. Consult your aircraft maintenance manual (AMM) for aircraft-specific details and guidance.

Commercial jets may be deiced either at the gate or—more frequently—at a designated deicing pad. During the deicing procedure, two to four deicing vehicles will start at the front of the fuselage and work their way aft spraying on the anti-ice fluid. The rule of thumb is high to low and front to back for the most even, thorough, and effective application.

Apply the fluid symmetrically so that both the left and right sides of the aircraft receive the same treatment. This helps to prevent uneven ice buildup which would even more adversely impact the aerodynamic stability of the plane.

Ice Removal: General Aviation

A general aviation pilot does not have the luxury of a dedicated ground crew that the airline pilot enjoys, but the small GA aircraft is no less susceptible to the dangers of icing conditions.

The best option to ensure a clean plane is to store it in a hangar if at all possible. If you need to brush your aircraft off, use a special soft-bristle brush that will not damage your plane. Hot water is also an option if you wipe it back off before it freezes.

Deicers work, but can be costly, and small aircraft can use the same Type I deicing fluids as commercial aircraft. If you do not have access to a deicing crew, Type I fluid may be self-applied using a hand-held sprayer, although this does decrease the holding time.

It's better to take a longer period of time to make sure all the ice is removed. Check the leading edge and the trailing edge of the aircraft. Get a step-ladder if necessary and look on top of the aircraft for removing snow and ice from critical surfaces.

Difference Between De-Icing and Anti-Icing Agents

De-icing removes existing buildup, while anti-icing agents aim to prevent ice formation and accumulation. Anti-icing fluids, with a higher glycol concentration, are applied within three minutes of de-icing to provide protection during takeoff.

-

Common Anti-Icing Fluid:

-

Type IV: A thick, green substance capable of withstanding temperatures down to -20°F.

-

Type II, III and IV anti-icing fluids are comprised of at least 50% and up to 100% glycol.

In some cases, such as with a thin layer of frost, an aircraft may be able skip the two-step process and instead opt for a one-step deicing and anti-icing procedure using a Type I deicer.

In other cases, such as when an aircraft is being prepared for an overnight stop, the two-step process will be necessary and a stronger, less diluted anti-icing fluid can be used.

FAQs About De-Icing

-

How long does de-icing take?

-

The times vary, light frost might only require 10-15 minutes, in snowy weather the process can take longer. Be patient, take your time to thoroughly remove all ice and always opt for safety first.

-

-

Where does de-icing happen?

-

It can occur at the gate or a designated de-ice pad, depending on the airport's facilities.

-

-

How much does it cost to de-ice a plane?

-

Costs vary based on the type of aircraft and the specific de-icing procedures required, but it can range from $1,000 to $13,000.

-

-

At what temperature do planes need to be de-iced?

-

De-icing is typically necessary when temperatures drop below 30 degrees or when freezing conditions cause a buildup of ice on the aircraft.

-

Takeaways

During cold, inclement weather, deicing is a vital step to safeguard your aircraft. Skipping or skimping on deicing is dangerous and can cause a crash due to the negative aerodynamic impact of accumulated frost, ice and snow.

Stay safe by following recommended deicing and anti-icing procedures so you have a clean aircraft before you take off.

More safety-focused reads to help you avoid aviation disasters:

Did you find this article helpful?

Do you think we missed anything important? Let us know in the comments below!