You're planning a night trip up north and then it happens—ice begins to form on your aircraft. The stakes are high: iced-over wings, clogged fuel tank vents, and obstructed engine inlets can dramatically affect your control, speed, and overall flight safety.

Are you prepared to handle flight into known icing conditions? Do you know the best strategies to protect critical surfaces from the dangers of ice buildup? Whether you fly general aviation or commercial jets, staying ahead of ice formation is a core part of winter flight operations.

Freezing conditions and ice are a serious hazard that can challenge every aspect of your flight. Ice accumulates on wings, engine inlets, and tail surfaces, impacting your control, performance, and visibility.

Don’t let icy conditions catch you off guard. This is where robust aircraft anti-icing and de-icing systems come into play.

In this article, we’ll delve into six essential systems, explaining how each one keeps you airborne safely when the temperatures drop. Let’s talk about how to ensure your aircraft remains in peak condition—even when winter weather tries to put a freeze on your flight plans.

SUMMARY

-

Aircraft anti-icing systems prevent ice accumulation on vital surfaces.

-

De-icing equipment removes ice once it has formed on the aircraft.

-

Bleed air systems deliver heat from the engine to wing and tail surfaces.

-

Chemical anti-icing systems use antifreeze solutions to chemically break ice formation on surfaces.

-

Inflatable boots, often on wing edges, expand and contract to remove accumulated ice.

What is the Difference Between Anti-Icing and De-Icing?

Anti-icing and de-icing might sound like they’re doing the same job, but they actually work at different stages of protecting your aircraft from ice-related hazards.

Anti-Icing

Anti-icing is part of a proactive ice protection system, and it's meant to be your first line of defense against ice adhering to your aircraft. These systems kick in as soon as you enter freezing temperatures or known icing areas. They work to constantly warm or treat the aircraft’s surfaces to prevent ice buildup.

You’ll usually find anti-icing on engines, wings, and windshields—critical areas where ice formation can severely compromise aircraft performance and pilot visibility.

De-Icing

De-icing is a reactive measure, designed to remove ice once it’s already there. Unlike anti-icing, de-icing systems don’t run continuously; they activate when needed, employing methods such as inflatable boots, heat, or chemicals to break ice away from surfaces.

Because the de-icing process may leave ice on the surface for short periods before it breaks off, pilots need to pay close attention to timing and activate the system before ice gets too thick.

6 Essential Aircraft Anti-Icing and De-Icing Systems Explained

Let’s take an in-depth look at six common anti-icing and de-icing systems that protect aircraft from structural icing. These are key for maintaining safe flight operations in low temperatures or freezing precipitation.

1. Bleed Air Systems

Bleed air systems are common on larger jets and turboprop aircraft. They channel engine bleed air (hot air) to provide heat to the leading edges, wing and tail surfaces, and other ice-prone areas.

This heated air keeps surfaces above freezing, preventing ice formation. Bleed air systems are reliable for continuous ice protection during long flights, though they can draw heavily on engine power. For this reason, they’re mainly found on aircraft with engines powerful enough to handle the additional energy demand.

2. Heated Leading Edges

Heated leading edges use either electrical or pneumatic heating elements to prevent ice buildup on the leading edges of the wings, tail, and other critical areas. This method maintains the aircraft’s aerodynamic shape, essential for consistent lift and handling.

For smaller aircraft that may not support bleed air systems, electrically heated edges are a popular choice. They offer a direct approach to anti-icing and work continuously to minimize ice accumulation in persistent icing conditions.

3. Chemical Anti-Icing Systems

Chemical anti-icing systems employ an antifreeze solution—commonly glycol-based—to disrupt or prevent ice formation. The fluid spreads over surfaces like fuel tank vents, pitot tubes, and wing leading edges.

Because they require minimal energy compared to heated systems, chemical anti-icing is a go-to solution for smaller aircraft. However, pilots must monitor fluid levels and replenish as necessary, especially on longer flights or in continuous icing.

Types of De-Icing and Anti-Icing Chemicals

In general aviation, physical methods like brooms and scrapers often help remove ice on the ground. Some airports, however, offer specialized chemical de-icing and anti-icing fluids for more thorough protection.

If you plan to use these services, reach out to the airport prior to flight. These services typically involve spraying glycol-based fluids on the aircraft to remove existing ice or prevent new accumulation.

Here are the most common fluid types:

-

Type I (Orange): The most common choice in general aviation. It’s a thinner, heated fluid sprayed onto the aircraft to quickly remove ice. While it offers a short window of protection, it does not remain on the surface for long.

-

Type II (Light Yellow): A thicker fluid designed mainly for larger, faster planes. It stays on the surface longer for anti-icing and then shears off during takeoff as airspeed increases. Not typically used on smaller aircraft since lower speeds may not effectively remove it.

-

Type III (Pale Yellow): A middle-ground fluid suitable for slower aircraft, including some general aviation planes. It provides extended protection without being so thick that it fails to shed at moderate airspeeds.

-

Type IV (Green): The thickest and longest-lasting fluid, used primarily by commercial airlines expecting severe icing. For general aviation, it’s usually more protection than needed, but vital for larger aircraft in extreme conditions.

4. Inflatable Boots

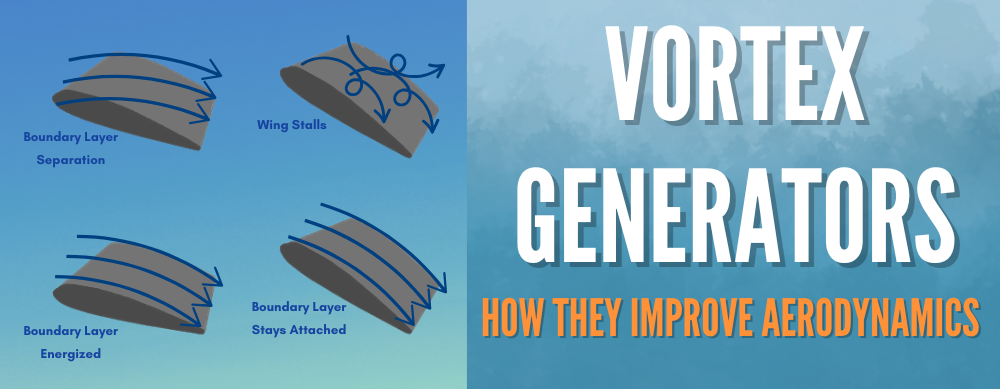

Inflatable boots are a classic de-icing system commonly found on control surfaces and wing leading edges. These rubber boots inflate and deflate rapidly, cracking and shedding accumulated ice.

Since inflatable boots are not always active, timing is crucial—activate them once ice begins to accumulate but before it becomes too thick to break off easily. This balance ensures a quick and efficient method to clear hazardous ice.

5. Pitot Tube Heaters

Pitot tube heaters are a small but vital piece of anti-icing equipment that guard your airspeed indicator from icing. Even minor ice inside a pitot tube can produce dangerously inaccurate airspeed readings.

Typically powered by electricity, pitot tube heaters keep the tube warm enough to prevent ice from forming. This ensures consistent, reliable data for safe navigation—an absolute must in winter weather conditions.

6. Engine Anti-Icing Systems

Engine anti-icing focuses on protecting the engine inlets and other critical engine components from ice buildup. It can use engine bleed air or electric heating elements to maintain ice-free inlets.

In turbofan and turbojet engines, even slight ice accumulation can disrupt airflow and damage internal components. By preventing ice formation at the intake, these systems safeguard engine performance and reduce the risk of engine flameout in freezing temperatures.

Frequently Asked Questions

-

What’s the difference between anti-icing and de-icing in flight?

Anti-icing prevents ice from forming on surfaces, while de-icing removes ice that has already formed.

-

How do inflatable boots work?

Inflatable boots expand and contract on wing edges, physically cracking and dislodging accumulated ice.

-

What surfaces on an aircraft typically need anti-icing?

Leading edges of wings, tail surfaces, engine inlets, and pitot tubes are common areas requiring anti-icing.

-

Can icing affect fuel tank vents?

Yes, fuel tank vents can clog due to ice. Adequate anti-icing measures ensure proper venting and safe fuel flow.

Takeaway

Understanding the capabilities and limits of each anti-icing and de-icing system is critical for safe winter flight operations. Reacting too late or relying solely on one method can leave you vulnerable to rapidly accumulating ice.

Prepare thoroughly by reviewing your aircraft’s Pilot’s Operating Handbook (POH), staying updated on FAA guidelines, and ensuring all systems are in top condition. With the right tools and strategic activation, you’ll be ready to tackle even the iciest skies.

Fly safely and stay ahead of winter weather!

Interested in Being Prepared for Winter?

Our guides are designed to help! Check out these resources for more information on winter flight safety and aircraft de-icing:

Did you find this article helpful?

Let us know in the comments! If you have any additional tips or questions about aircraft icing and winter operations, we’d love to hear from you.