Regardless of whether you are an aviation enthusiast, a pilot, or just curious about planes and their anatomy, understanding the different types of airplane flaps is critical.

In this article, we will take a look at why wing flaps are essential for aircraft performance and safety, as well as how they contribute to the complexity of flight movement.

A Brief History of Flaps

In 1903, the Wright Brothers flew the first flight in Kitty Hawk. Just over a decade later, aircraft designers unleashed a revolutionary invention—the wing flaps!

These flaps could change the shape of a plane's wings, allowing it to fly higher and farther. Ever since then, scientists have kept on dreaming up ways to refine wing flap designs and make flying easier for pilots, from takeoff to landing.

What are Flaps and Why Do They Matter?

Flaps are incredibly vital components of an aircraft's wings that play a crucial role in flight. These movable surfaces are located on the trailing edge of the wings, enabling pilots to enhance lift, control, and maneuverability during different phases of flight.

Having an understanding of wing flaps is a must for having an aptitude of aerodynamics and the exhilarating world of flying.

Onto the wing flaps!

1. Plain Flaps

The first type of wing flap developed was the plain or conventional flap.

This attaches to the trailing edge of the wing and normally remains in line with the rest of it. When extended, it hinges and pivots down. This increases airflow separation at the wing's trailing edge, creating more drag.

Thanks to its ability to let pilots fly steeper descents without increasing airspeed, plain flaps were popular when they debuted in 1916. Nowadays, newer designs have made these types of wing flaps less popular.

2. Split Flaps

Split flaps, as the name implies, are made of two portions. The upper portion of the split flap is a fixed extension of the top trailing edge of the wing while the mobile portion is mounted on the lower surface of the wing. This mobile portion hinges and pivots down much like a plain flap, and has similar drag producing characteristics. This design does produce somewhat more lift than the plain flap design as it maintains the surface area of the fixed portion of the wing even when the wing flaps are deflected.

Split flaps were introduced in the 1930s and were common on military aircraft like the Douglas DC series. They are a rare sight today outside of historic warbirds at airshows since at full deflection, the flap acts as a spoiler and significantly increases drag coefficient without correspondingly substantial benefits to lift.

3. Slotted Flaps

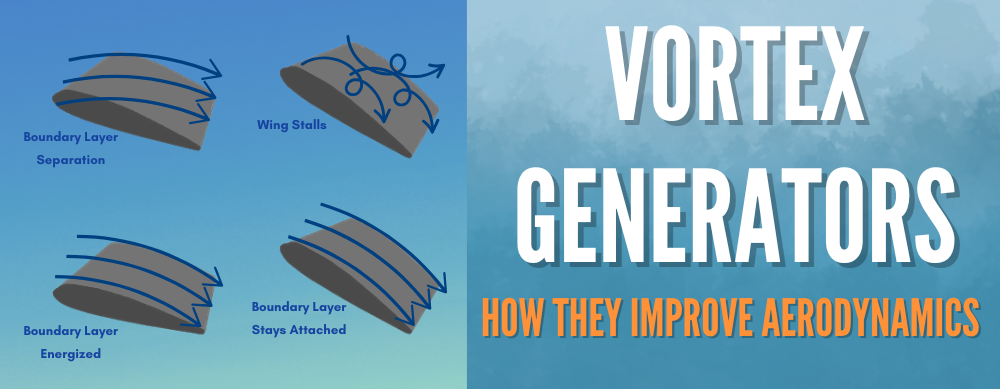

The most common type of airplane wing flaps in use today are slotted flaps. Slotted flaps attach to the trailing edge of the wing and get their name from the gap or slot that opens between them and the wing when they are extended.

The magic of slotted flaps and the reason for their prevalent use in both large and small aircraft lies in the aerodynamic nature of the slot.

With flaps extended, when the high-pressure air that is traveling along the bottom of the wing reaches the slot, it flows through and emerges on the upper side of the flap. This influx of high-pressure air has a re-energizing effect on the wing’s boundary layer. This delays airflow separation resulting in more lift with less drag.

4. Fowler Flaps

Fowler flaps are like a large extension of slotted flaps. Fowler flaps have many extension settings with the flaps themselves being extended on a set of rails or tracks. Slots between each of the flap segments function like the slots of a slotted flap to refresh the wing’s boundary layer with a fresh dose of high-pressure air.

Due to their length, rather than simply extending back from the wing, when fully extended, slotted flaps curve downwards. This allows fowler flaps to increase not only chord but also camber. The further the extension, the more drag is generated while lift gains taper off. Fowler flaps are often used on large jets where their increased wing area helps generate lift for takeoff.

5. Slotted Fowler Flaps

This design improves the performance of the fowler flap by incorporating the boundary layer energizing features of the slotted flap.

6. Gouge Flaps

Gouge flaps are a variety of split flaps where rather than the bottom segment merely hinging downward as with a standard split flap, it instead slides back on a track system allowing for the increase of both chord and camber.

Gouge flaps are an uncommon variety of wing flaps developed in the mid-1930s. Released around the same time as Fowler flaps, gouge flaps lacked the extra lift generation capabilities generated by the slots on the Fowler flaps.

Ultimately gouge flaps failed to be widely adopted and were specific to the Short Brothers aircraft where they were installed on both the Short Stirling and Short Sunderland.

Sunderland.

7. Junkers Flaps

Junkers flaps generate more lift but also more drag than either plain or split flaps which were in use around the time the junkers flaps were developed. Junkers flaps maintain the mechanical simplicity of the plain flap, as they are essentially a plain flap that is fixed just below the trailing edge of the wing.

A hinge connects the trailing edge of the wing to the leading edge of the wing flap. When not in use, the flap is folded under the wing where it generates drag. Upon deflection, the flap hinges out to create a slotted pain flap configuration.

The Junkers Flaps were designed by the Junkers aircraft company and were used on their Junkers Ju 52 as well as the Junkers Ju 87 Stuka. Modern ultralights like the Denney Kitfox use a similar flap configuration.

8. Zap Flaps

Zap Flaps are on the list of the more obscure type of airplane flaps ever thought up. These flaps were developed in the early 1930s and were rarely used commercially except on the Northrop P-61 Black Widow.

Edward Zaparka, the inventor after whom the zap flaps were named, designed these types of flaps as innovative lift devices to provide increases to both the maximum lift and drag capacities of aircraft.

The Zap flap operates on a split flap design with the movable bottom portion sliding aft on tracks as well as hinging down. This dual articulation increases both the camber and effective surface area of the wing.

9. Krueger Flaps

Contrary to other flaps which are standardly installed on the trailing edge of the aircraft’s wings, Krueger flaps are positioned on the bottom of the leading edge.

They hinge down and forwards when deployed, thereby increasing the camber of the wing and generating more lift. Krueger flaps were invented in 1943 and have since been installed on many swept-wing aircraft. Boeing 747s use Krueger flaps while the Boeing 727 was built with a blend of Krueger flaps and outboard slats.

10. Gurney Flaps

Gurney flaps are much smaller than other varieties of flaps. A Gurney flap consists of a small fixed tab extending down at a right angle from the trailing edge of the wing.

The tab’s height is usually equal to 1-2% of the wing chord. Gurney flaps are named for the racecar driver who utilized them to improve the handling and performance of his racecar in the 1970s.

In the aviation arena, the most common modern application of Gurney flaps is on helicopters like the Sikorsky S-76B. These small wing flaps help to enhance airfoil efficiency and alleviate control problems without the need for an aircraft redesign.

BONUS. Flexible Flaps

The story of airplane flap design is not over yet. One of the most promising modern innovations in the works is the idea of flexible flaps. Imagine being able to change the shape of your aircraft’s wings mid-flight to adapt your lift-to-drag ratio for the current conditions.

The premise behind flexible flaps is to use a seamless, shape morphing aviation grade material that is rated to flex through a range of motion from -9° to + 40°. NASA and the United States Air Force have been working with multiple private companies to design, develop, and test the flexible flaps that could soon be a commercial reality. If flexible flaps come to fruition, they are poised to reduce in-flight noise and improve fuel efficiency.

Go Soar With Confidence!

Now equipped with knowledge of the ten different types of wing flaps, you can impress other aviation enthusiasts or your flight instructor during your next lesson!

Like Our Content?

Don’t miss out on the latest aviation updates. Sign up for our newsletter to receive coupons and special promotions!

100% free, Unsubscribe any time!